Planetary Gearbox

Custom Made

Agknx provides customer-based planetary gearbox solutions with a variety of material and gearbox function options. Planetary gearboxes can be combined with motors, including DC motors, stepper motors, and coreless motors, to achieve high output torque, smooth output speed, and high work efficiency.

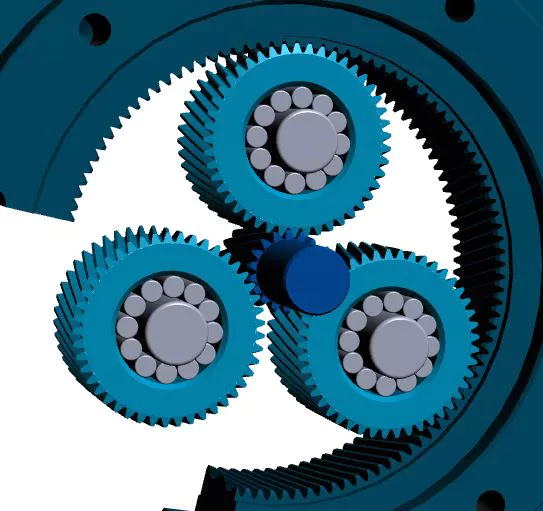

Planetary gearbox is a commonly used reducer, consisting of planetary gears, sun gears and outer ring gears. The sun gear is usually placed in the center, and the planet gears rotate around the sun gear, receiving torque from the sun gear. The outer ring gear (referring to the lower casing) meshes with the planetary gears. Agknx provides optional motors such as brushed DC motors, brushless DC motors, stepper motors, hollow cup motors, etc., which can be matched with miniature planetary gearboxes for better performance.

The skills required to manufacture planetary gearboxes are the same as those required to manufacture any other type of precision gearbox. Agknx is a leading precision gear manufacturer specializing in custom cut and ground gearboxes. We have an extensive portfolio of gearbox production capabilities, including the ability to produce all the individual gearboxes that make up a planetary gearbox system. For specific manufacturing capabilities such as minimum and maximum diameters, pitch diameters and face widths, please visit our Gearbox Capabilities page. Please note that we do not manufacture gearboxes.Agknx also has extensive experience in gear engineering and design. Whether you need to design a drivetrain from scratch or need help with a redesign, we’ll work with you through the process to ensure your drivetrain is designed and manufactured with precision. Engineering services include reverse engineering, design for manufacturability, prototyping and redesign.

Manufacturing planetary gearboxes

Planetary Gearbox Special Features

Due to the nature of the design, the planetary gear system excels at load distribution. Whereas in a traditional gear system it relies upon the movement and transmission between small and large gears, this is not the case in the planetary gear system.

In the planetary gear system the load is distributed throughout the planet gears. In this way issues such as broken gear teeth which occur in traditional systems when under heavy loading, do not occur frequently within a planetary gear set.

Speed reducers for the transport industry, Petrochemical Industry, wind power generation, steel industry and textile industry are a critical part of the company infrastructure. We have designed our planetary speed reducers so that the components are dimensionally interchangeable with components from other brands. We also make sure to keep a stock of all of the major components so that we can respond rapidly to any parts requests from our customers.

Planetary Gearbox Application

- Lifting Systems

- Heavy Machinery

- Transport Industry

- Textile Industry

- Steel Industry

- Mining

- Engineering Machinery

- Petrochemicals

- Construction Machinery

- Wind Power Generation

Industries and Applications that Use Planetary Gearing

Planetary gears are designed for a wide range of applications including automotive and off-road transmissions, wheel drive motors, industrial conveying applications and more. In fact, even a seemingly simple application like a bicycle uses planetary gears to power the shifting mechanism. Additionally, they can be used as powertrains between combustion engines or connected to electric motors.

Planetary Gearing in Unique Processing Applications

Because planetary gears are known for their high ratio potential, compact design and robustness, they are ideal for unique applications. In industry in particular, planetary gears are used to power forestry applications including log decks, debarking equipment, sawing applications, pulp washers and vacuum filters. Planetary gear drives are also used in sugarcane applications, the phosphate industry, steel mills and in asphalt and cement conveyors, mixers and drums.

Advantages of Planetary Gearbox

1. High torque: With more teeth in contact, the mechanism can transmit and withstand greater torque in a more uniform manner.

2. Durable and efficient: The bearing can reduce friction by connecting the shaft directly to the gearbox. It allows for better rolling and smooth running, simultaneously enhancing efficiency.

3. Impressive precision: The rotation angle is fixed, which improves the accuracy and stability of the rotation movement.

4. Compact size: The planetary gear motor can be compact and small due to the planetary structure, in which multiple gears mesh together and orbit around a sun gear.

5. Low-noise: The multiple gears enable more surface contact. Rolling is much softer, and jumps are virtually nonexistent.

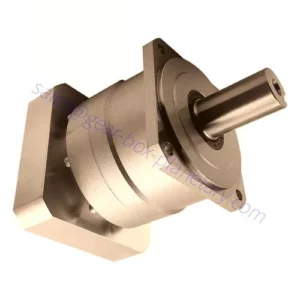

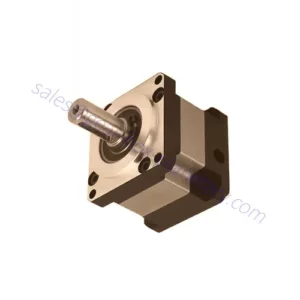

Planetary gearbox with output shaft

Planetary gearboxes with output shafts are suitable for various drive solutions.

Output shafts are available in a variety of models, such as output shafts with feather keys for positive fit and reliable power transmission. Feather keys are a common connecting element in many drive assemblies and allow you to make a quick and safe connection between a planetary gearbox with output shaft and your application.

Planetary gearboxes with smooth output shafts are ideal for press fit couplings. This allows you to achieve maximum torque transfer even in reverse mode.

You can also connect a planetary gearbox with an output shaft to a drive system with a pinion. Using a toothed output shaft according to DIN 5480, additional drive components such as pinions with internal gears can be perfectly mounted very simply.

The input flange of the planetary gearbox is individually adapted to the motor. A compact planetary gearbox with output shaft and servo motor increases your flexibility.

Due to the low inertia of the rotating output shaft, planetary gearboxes with output shafts are the ideal solution for many dynamic applications. The versatility of planetary gearboxes with output shafts gives you maximum flexibility in choosing the right product for your application.

If despite the compactness of our planetary gearboxes you need a shorter gearbox, you can find right angle planetary gearboxes with output shafts here.