In the world of mechanical engineering, there are few components as essential and versatile as gearboxes. These ingenious devices transmit power, change speed, and alter torque between different mechanical components. Among various gearbox designs, the high precision planetary gearbox stands out as a pinnacle of engineering excellence.

Understanding Planetary Gearboxes

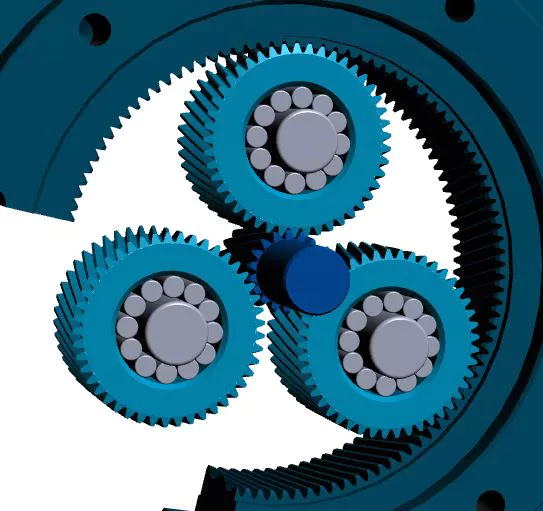

Planetary gearboxes, also known as epicyclic gearboxes, consist of a central gear, known as the sun gear, surrounded by multiple smaller gears, called planet gears, all encased within a ring gear. The arrangement resembles a miniature solar system, hence the name. Each of these components plays a critical role in determining the overall performance and capabilities of the gearbox.

Advantages of High Precision Planetary Gearboxes

Exceptional Power Transmission: High precision planetary gearboxes provide excellent power transmission efficiency, allowing for reliable and accurate torque transfer between input and output shafts. This makes them ideal for applications requiring high torque and precision, such as robotics, industrial machinery, and aerospace systems.

Compact Size: The design of planetary gearboxes offers a significant advantage in terms of size and weight. By distributing the load across multiple planet gears, these gearboxes achieve higher torque density compared to other gearbox types. The compact size of high precision planetary gearboxes enables their integration into various space-constrained applications.

Versatility: The modular nature of planetary gearboxes allows for flexibility in configurations. Additional gear stages can be added to achieve higher gear ratios, enabling a wide range of speed options. Moreover, the input and output shafts can be aligned in various ways, enabling different mounting orientations and making them adaptable to different applications.

High Torque Density: High precision planetary gearboxes excel in providing a high torque output relative to their size and weight. This attribute is particularly valuable in applications that demand high power density and compactness, such as robotics, medical devices, and automotive systems.

Precise and Repeatable Motion Control: With their multiple gear stages and balanced load distribution, high precision planetary gearboxes offer precise motion control and positional accuracy. This makes them an ideal choice for robotics, CNC machines, and other applications that require accurate and repeatable movements.

Applications of High Precision Planetary Gearboxes

Robotics: High precision planetary gearboxes are extensively used in robotic systems for precise control of joint movements. They enable smooth and accurate motion, allowing robots to perform delicate tasks with precision, such as assembly, pick-and-place operations, and surgery.

Industrial Machinery: In various industrial applications, such as conveyor systems, machine tools, and packaging machinery, high precision planetary gearboxes play a crucial role. Their compact design and high torque density facilitate efficient power transmission, ensuring optimal performance and reliability.

Aerospace and Defense: The aerospace and defense sectors heavily rely on high precision planetary gearboxes for critical applications, including actuator systems, landing gear mechanisms, missile guidance systems, and more. Their high torque capacity, compactness, and precise motion control are vital in these demanding environments.

Renewable Energy: Wind turbines and solar tracking systems require gearboxes that can withstand high torque, provide precise speed control, and operate reliably in harsh conditions. High precision planetary gearboxes meet these requirements and contribute to the efficient generation of renewable energy.

High precision planetary gearboxes represent a pinnacle of mechanical engineering, offering exceptional power transmission, compactness, versatility, and precise motion control. Their contributions can be seen in various industries, from robotics and industrial machinery to aerospace and renewable energy systems. As technology continues to advance, we can expect further enhancements and innovations in high precision planetary gearboxes, making them even more indispensable in modern engineering applications.

Edited by Zqq.